Water softening systems are designed to improve water quality in homes, hotels, restaurants, industrial facilities.... Residential water supply guarantees that the water supplied is suitable for human consumption, but it often contains calcium and magnesium salts, which are the cause for water hardness. These minerals can originate several problems in boilers, heaters, washing machines, dishwashers, pipes, coffee machines, humidifiers and many other appliances.

Softened water provides healthier personal hygiene, important savings in energy consumption and detergents, and can also prevent the build-up of limescale which can damage hydraulic installations.

In summary, softened water helps to improve the quality of everyday life.

BENEFITS OF SOFTENED WATER:

• Healthier personal hygiene. Smooth skin, soft hair, better shaving, etc.

• Food tastes better. Cooking times can be reduced, allowing food to retain all its flavour.

• Softer clothes. It prevents roughness and makes clothes feel better, colours look brighter and garments last longer.

• Reduces energy consumption. It helps water heating elements to work more efficiently by preventing limescale build-up which can act as an insulator.

• Saves money. It reduces the amount of detergent and cleaning products needed, thereby reducing their impact on the environment.

• Makes cleaning easier. It avoids the generation of hard-elimination substances.

• Extends the working-life of our appliances. It prevents the build-up of limescale and keeps appliances in good condition, maintaining performance levels and extending the life-cycle of the appliance.

• Minimises breakdown. It reduces maintenance work and the risk of breakdown in electrical appliances, boilers and heaters.

• Reliable. Reliable and easy to install systems that are economical to run and maintain.

WATER SOFTENING PROCESS

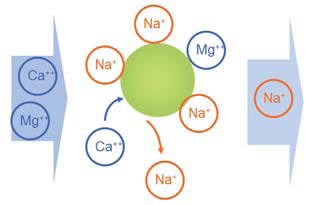

Water softening is a process through which cations that cause water hardness (calcium and magnesium) are eliminated and replaced by sodium, forming more soluble salts and avoiding its precipitation and incrustation. Ion exchange resins are small polymer beads with a highly developed structure of pores on the surface which have greater affinity for calcium and magnesium. Ion exchange resins regeneration is made with sodium chloride (common salt) especially designed for water treatment.

WATER SOFTENING STAGES

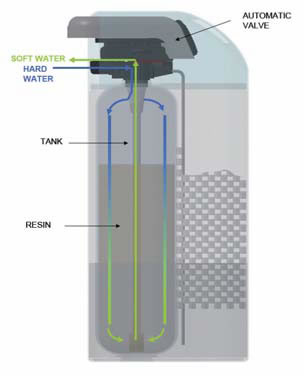

SERVICE

- Water to be treated flows through the resin layer.

- Ion exchange is performed.

- Calcium and magnesium cations are retained in the resin.

- Sodium cations are released into water.

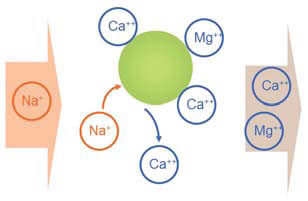

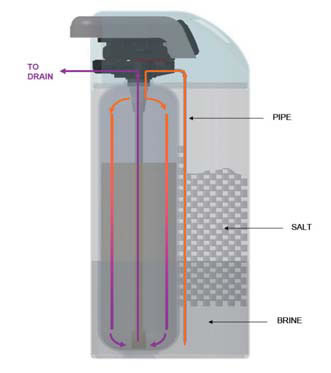

REGENERATION

- Exchange capacity of the resin is limited; when most sodium cations have been already exchanged in the resin, the regeneration process should be performed.

- A brine saturated solution (Sodium Clhoride) is introduced.

- Reverse exchange process → resin regeneration.

- Sodium cations saturation from the brine solution recovers resin to its original state.

- The resulting concentrated solution of calcium and magnesium cations are directed to the drain.

- System prepared for new cycle after rinsing.

Basic stages for this process are:

- Service.

- Backwash.

- Recharge and slow rinse.

- Fast rinse.

- Filling up the brine tank.

TYPES OF WATER SOFTENERS

A very important factor to take into account in order to choose a water softener are the type of control valves to be used.

- Time clock regeneration: The regeneration is performed by a timer, which can set the day and the time to start regeneration.

- Mechanical metered regeneration: The control of the regeneration is made indicating the water demand, calculating water hardness and exchange capacity to schedule the regeneration accordingly. Water consumption will be detected with a meter and regeneration will be start according to the settings.

- Electronic metered regeneration: Includes a micro processed system that allows the user to interpret the installation consumption and exchange capacity data of the water softener, generating statistical calculations of average consumption, determining the right moment for regeneration.

- Proportional metered regeneration: The micro processed system is very similar to the previous one. The difference is in the salt consumption adjustment and regeneration times performed by the controller when the cycle is started, according to the real exhausted exchange capacity.

PRODUCT FEATURES

- Automatic water softeners for hardness elimination by ion exchange. Compact assembly. Polyethylene cabinet.

- High chemical resistance Epoxy resin cylinder with reinforced fiberglass. Filament winding thread with alternate helical and circumferential layers. PE internal liner suitable for potable water. Fiberglass reinforced thread. Pressure tested to 15 bar.

- LOGIX Series controller.

• User friendly. Easy adjustment.

• New direct drive camshaft system design for greater mechanical reliability.

• Fast swing motor.

• Opto-electronics positioning system.

• Cutting-edge electronics. Non-volatile memory.

• Digital display.

• Built-in battery. 8 hours power back up.

• 3 possible settings for regeneration dosage:

• High - 200 gr/l, Standard - 120 gr/l, Low - 40 gr/l

- Two control possibilities:

Time clock. Electronic LOGIX 740 Controller. Options for programming regeneration frequency:

daily, weekly or in cycles of 1 to 99 days.

Metered. Microprocessed LOGIX 760 Controller. On water demand control. Registration of past operating values.

- 255/700 automatic valve, made of Noryl, mounted on the top of the FRP tank. Stronger, redesigned camshaft. It incorporates a mixer device to adjust residual hardness.

• Supplied with high capacity food grade resin for optimum performance.

• 1” male connection in Noryl.

• Operating pressure 2 to 7 bar.

• Operating temperature 2º to 35ºC.

• Electrical power supply 220V-12V (transformer included).

• Options: 1” Noryl by-pass (-3); kit micro switch (-K); salt sensor (-S); 742-762 controller (-A); safety brine valve (-B).

|

Resin,

litres

|

Max. flow

m3/h |

Capacity

m3 x °f |

Salt

consumption

(kgs) |

| 10 |

1.4 |

65 |

0.9 |

| 15 |

1.9 |

98 |

3.2 |

| 20 |

2.4 |

130 |

4 |

| 30 |

2.7 |

195 |

6 |

Resin,

litres |

Capacity, m3of softened water between regenerations |

| Water hardness |

| 20°f |

30°f |

40°f |

50°f |

60°f |

70°f |

| 10 |

3.3 |

2.2 |

1.6 |

1.3 |

1.1 |

0.9 |

| 15 |

4.9 |

3.5 |

2.4 |

2.1 |

1.6 |

1.5 |

| 20 |

6.5 |

4.3 |

3.3 |

2.6 |

2.2 |

1.9 |

| 30 |

9.8 |

6.5 |

4.9 |

3.9 |

3.3 |

2.8 |

DIMENSIONS:

Resin,

litres |

A,

mm |

B,

mm |

C,

mm |

D,

mm |

E,

mm |

F,

mm |

| 10 |

665 |

320 |

500 |

435 |

465 |

75 |

| 15 |

1130 |

320 |

500 |

900 |

930 |

75 |

| 20 |

1130 |

320 |

500 |

900 |

930 |

75 |

| 30 |

1130 |

320 |

500 |

900 |

930 |

75 |